Speaking from the nature of the temperature sensor, Moisture in the air is the main cause of failure for thermistor-based temeperature sensors that are exposed freeze/thaw cycles such as in refrigeration applications。

The repeated thermal cycles result in weakened or broken bonds between components, Moisture enters the probe causing thermistor failure.

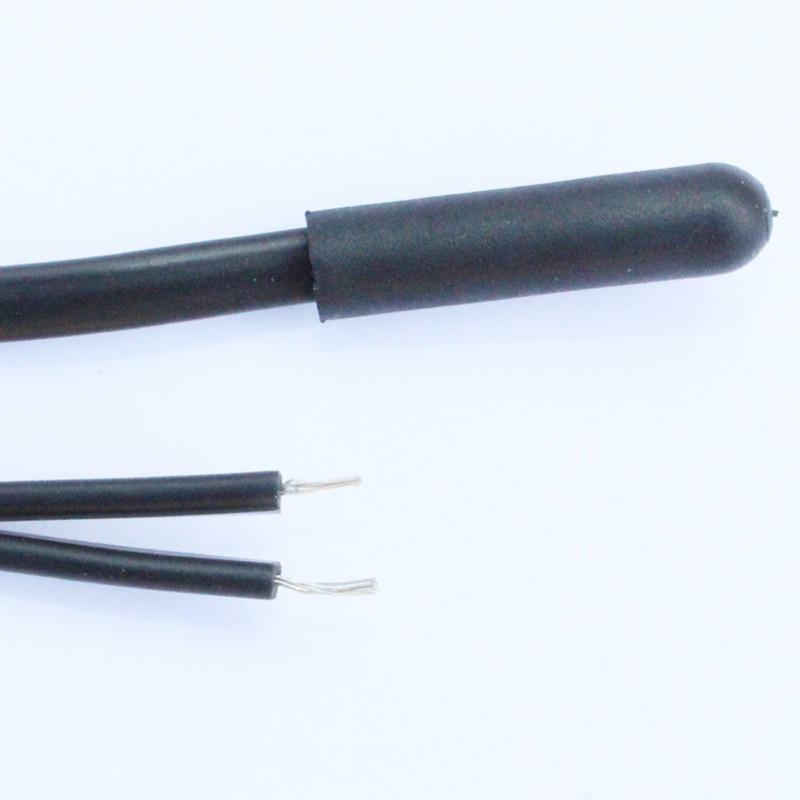

It is well known that thermistors are ideal sensing devices for applications with operating temperatures ranging from -55℃ to +125℃, Thermistor probes are used in refrigeration applications where temperatures range from -40℃ to +105℃, The sensor are mounted to evaporator coils, discharge lines and inside cabinets among other locations, While thermistor probes are perfectly suited for these temperatures, But the applications can be very harsh and can ultimately lead to premature failure. The harsh operating environment comes from the effort to maximize cooling efficiency, automatically defrost and minimize energe usage.Evaporator coils within a refrigeration system are heated as needed in order to bring the temperature of the evaporator coils from -40 ℃ to 100℃ to remove the frost from the coils and fins to ensure efficient and effective cooling. While this temperature cycle is well within the previously stated operating temperature range for thermistor elements, It does present challenges for the various materials that are used in creating a fully assembled thermistor probe. Materials used ( including extension cables, housings, encapsulation compunds, etc.) must be suitable for the environment and a sealing method as well as all materials must serve this purpose and keep moisture from reaching the thermistor element, Once moisture enter the probe and reach the thermistor element the sensor will fail prematurely due to corrosion.

Because of the different thermal expansion coefficient of different materials, The typical epoxy resin potted temperature probe will form the moisture channel naturally during the repeated freezing/ thawing cycle in refrigeration application, The moisture will enter the channnel and reach the thermistor element, Leading to sensor failure is only a matter of time sooner or later. In recent years many companies began to develop the overmolded temperature sensor with the different overmolding technology to solve this issue and achieved the rapid progress.

Based on the above situation, ATC decided to develop a temperature sensor that is rated to IP68, Our goal is to provide the customer more stable and reliable overmolded temperature sensor, To achieve our goal we establish a new production line .

Our company are specialized in IP68 rated waterproof overmolded temperature sensor development and manufacturing as long as 10 years. The sensor that is rated to IP68 gets the utility model patent certificate in the year of 2009 and the invention patent certificate in the year of 2013, Then we own the independent intellectual property rights, Our overmolded temperature sensor shows excellent performance in the harsh freeze thaw cycles, especially can maximize the air conditioning and refrigerator equipment life whichis used in the very harsh freeze thaw environment.

Our products web link: https://www.atcsensing.com/category/temperature-sensors/intelligent-home-appliances/refrigerator/